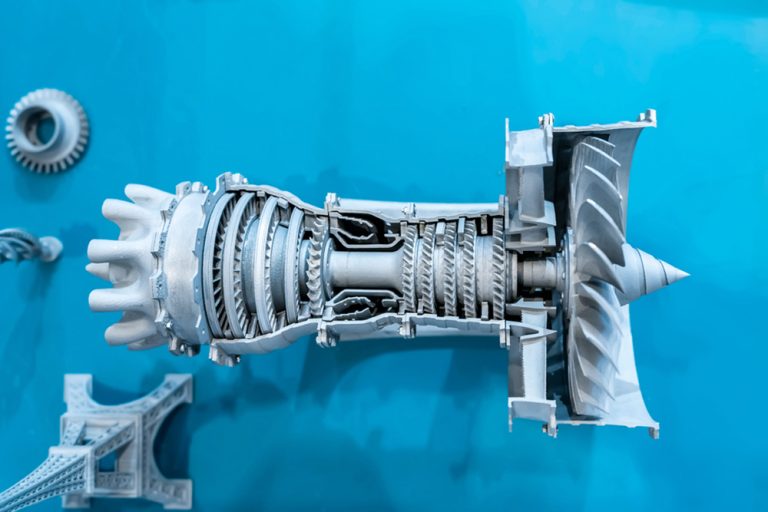

The Rotating Equipment course offers an extensive study of the principles and practices essential for the design, operation, and maintenance of rotating machinery used in industrial applications. Spanning 12 weeks (about 3 months), this course covers key concepts such as the types and functions of rotating equipment, including pumps, compressors, turbines, and motors. Participants will delve into advanced topics such as vibration analysis, alignment techniques, and performance optimization. Emphasis is placed on applying industry standards and best practices to ensure equipment reliability, efficiency, and safety. Through practical case studies and hands-on projects, attendees will gain experience in troubleshooting common issues and implementing effective maintenance strategies. The course also covers the latest advancements in rotating equipment technology and their applications. By the course’s end, participants will have the skills necessary to design, analyze, and maintain rotating machinery, addressing complex challenges and enhancing their expertise in mechanical engineering.

Course Brief

The Rotating Equipment course is designed to provide in-depth knowledge and skills in the design, operation, and maintenance of rotating machinery used across various industries. This course covers fundamental principles, advanced techniques, and industry standards essential for ensuring the reliability and efficiency of rotating equipment.

About the Course

- Duration:12 weeks (about 3 months)

- Mode: Online

- Level Intermediate to Advanced

- Prerequisites:Basic understanding of mechanical engineering principles and machine dynamics

Key Points of the Course

- Comprehensive Curriculum: Covers both fundamental and advanced concepts in rotating equipment.

- Practical Insights:Includes real-world case studies and hands-on projects.

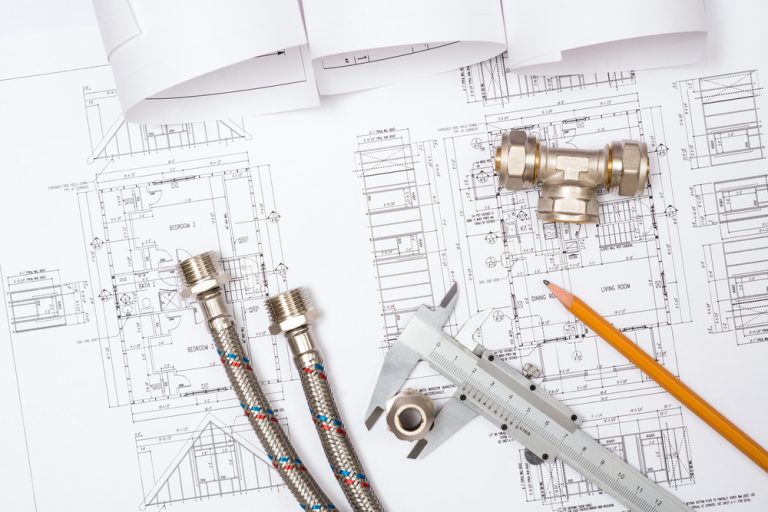

- Industry Standards: Emphasis on relevant standards such as API, ISO, and ASME.

- Software Training: Proficiency in industry-standard design and analysis tools.

- Expert Guidance:Learn from experienced professionals with extensive industry knowledge.

Course Objectives

- Master Rotating Equipment Principles: Understand the core principles of rotating machinery.

- Design and Analyze Equipment: Develop the ability to design, analyze, and troubleshoot rotating equipment.

- Apply Industry Standards:Gain proficiency in applying relevant codes and standards in rotating equipment design and maintenance.

- Use Advanced Tools: Learn to use software tools for design, simulation, and analysis of rotating equipment.

- Enhance Problem-Solving:Improve problem-solving skills through practical applications and projects.